Engine Driven System

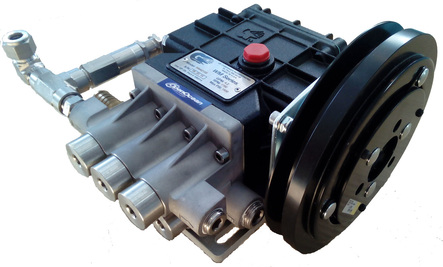

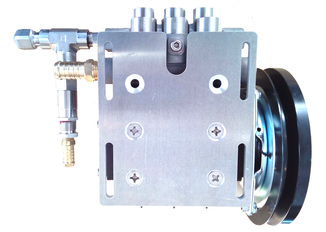

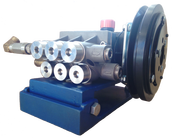

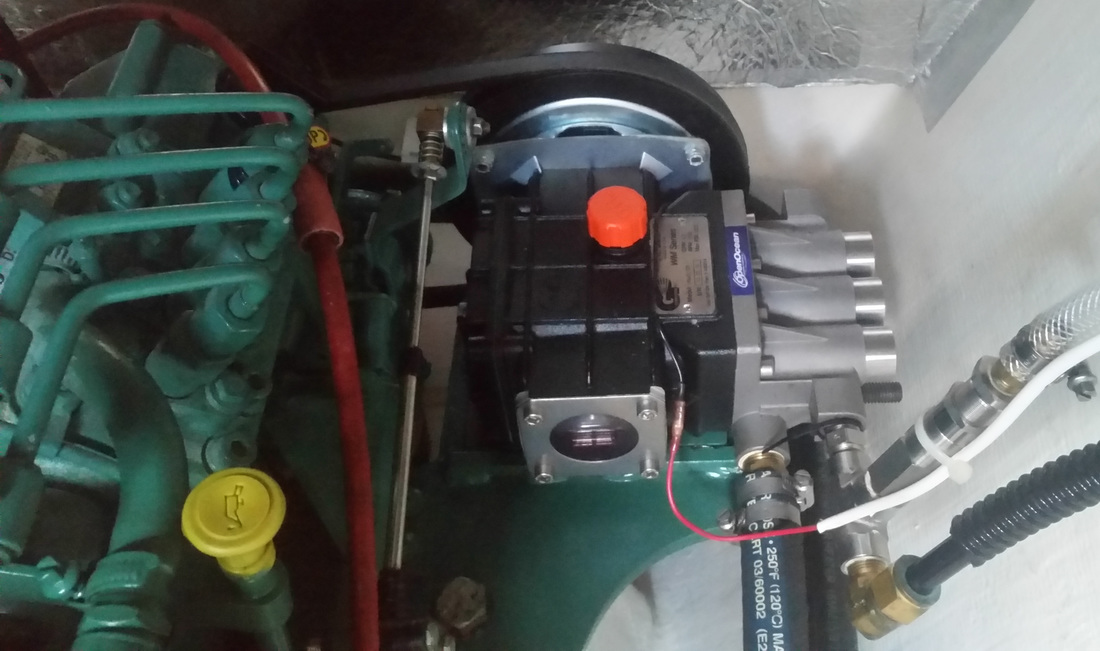

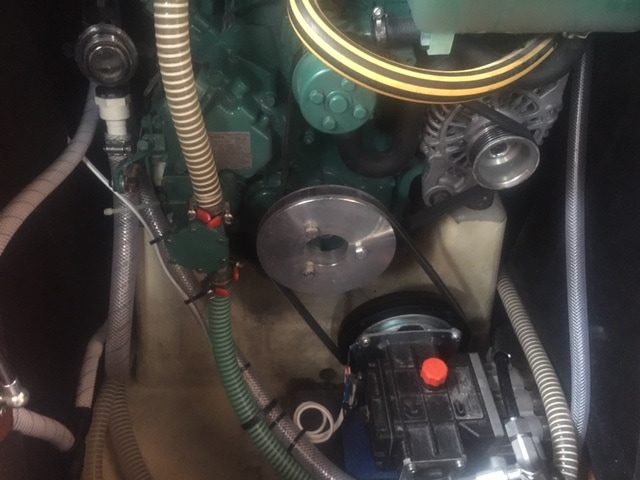

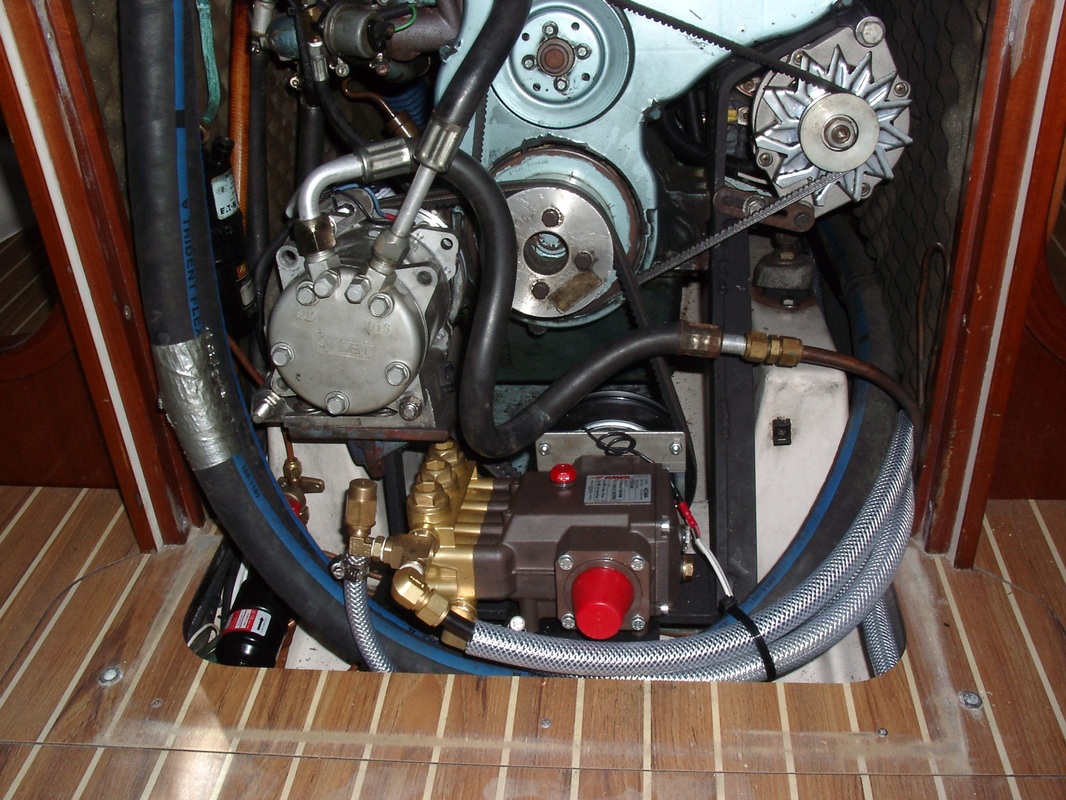

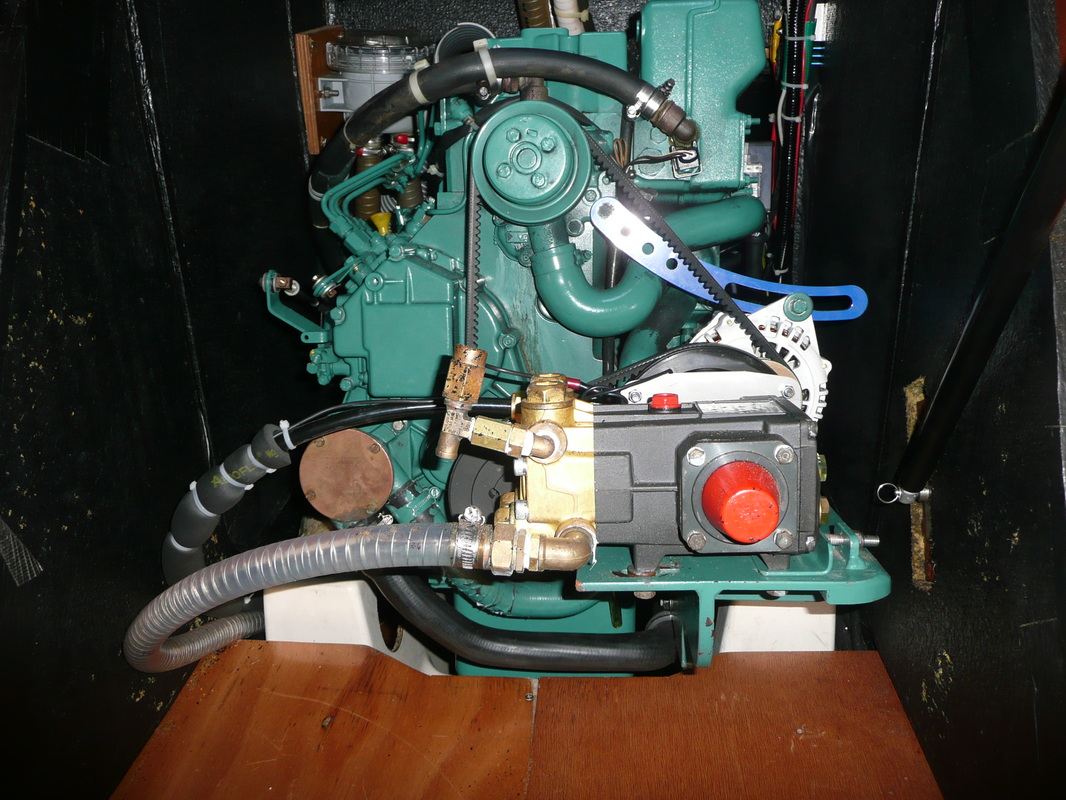

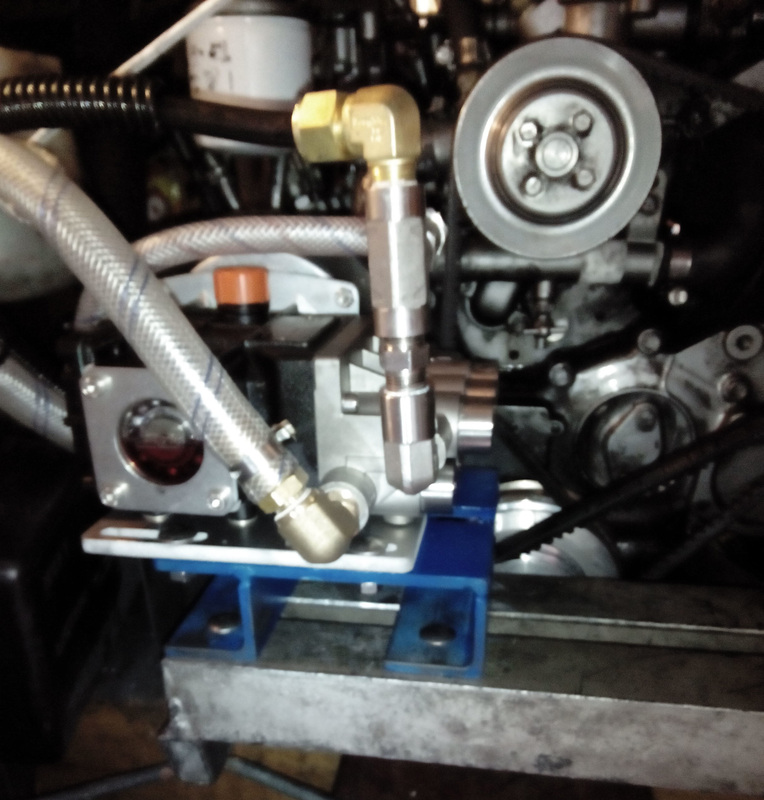

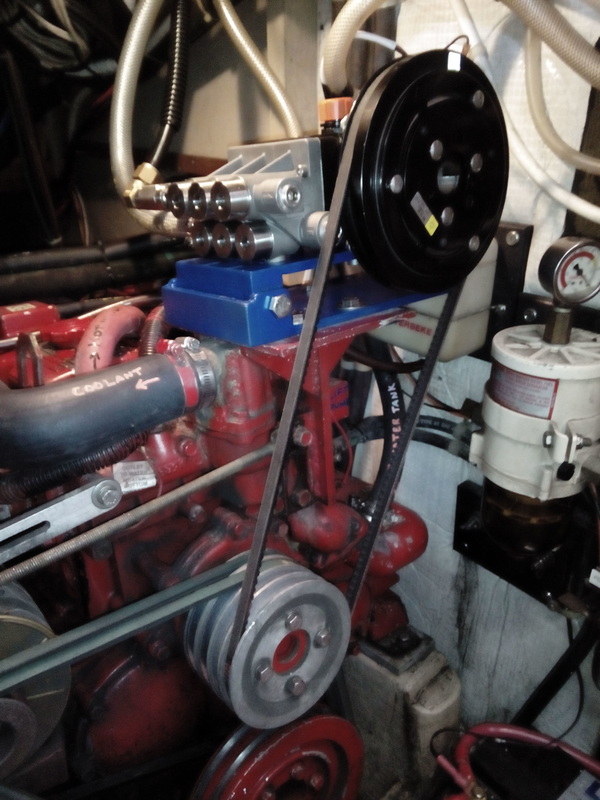

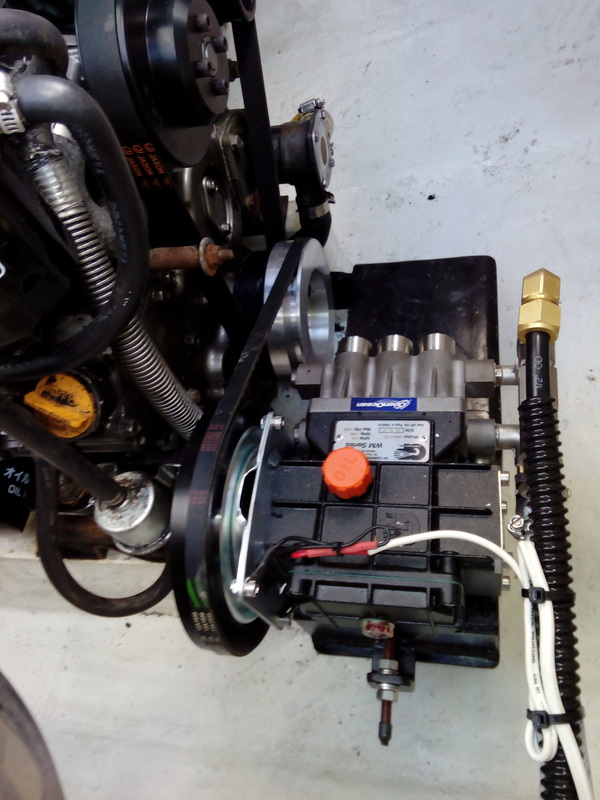

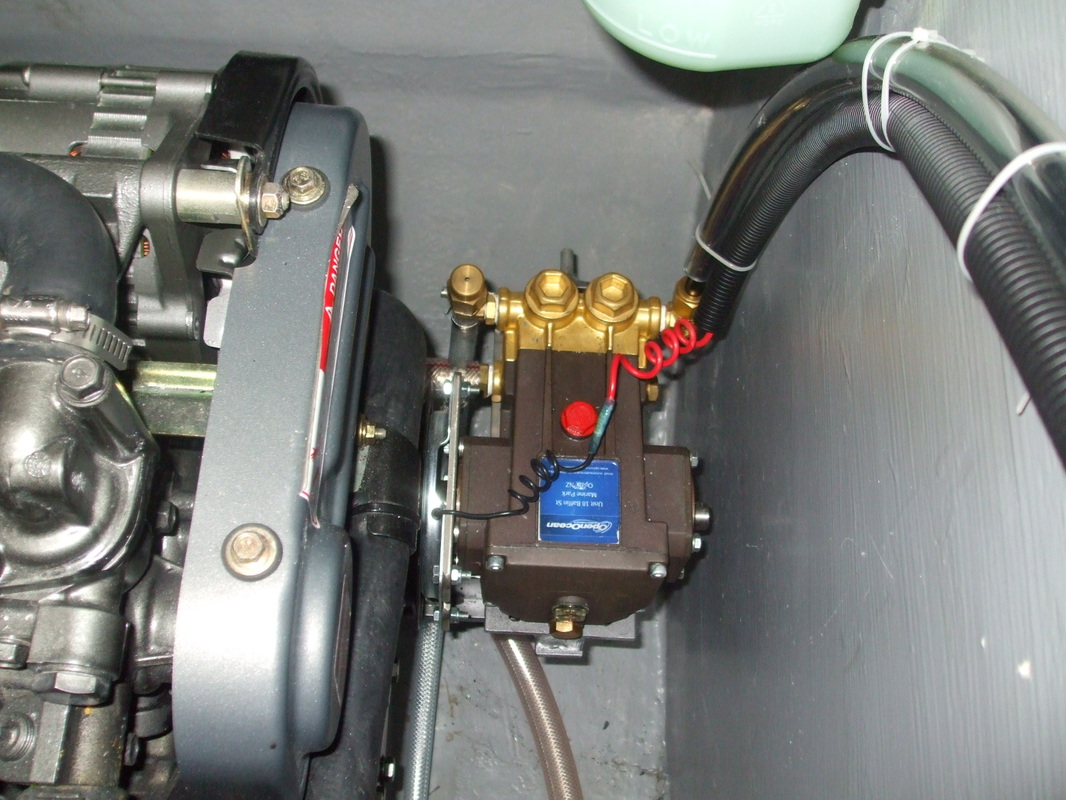

The engine driven model is an excellent way to utilize your engine running time to produce large quantities of water. The high pressure pump mounts on your engine or generator via an electric clutch driven by one “A” section belt.

All Open Ocean water makers have manual flush systems as standard. However, an automatic flush system is available as an option.

Units are modular in design allowing you to utilize unused areas. Increase your fresh water production from 80 ltrs per hour to 240 ltrs per hour by simply adding extra membranes.

Open Ocean is of the belief that water makers are no longer a luxury item, but an essential piece of equipment to provide superior quality water for all of your requirements.

Components included:

- Control Panel

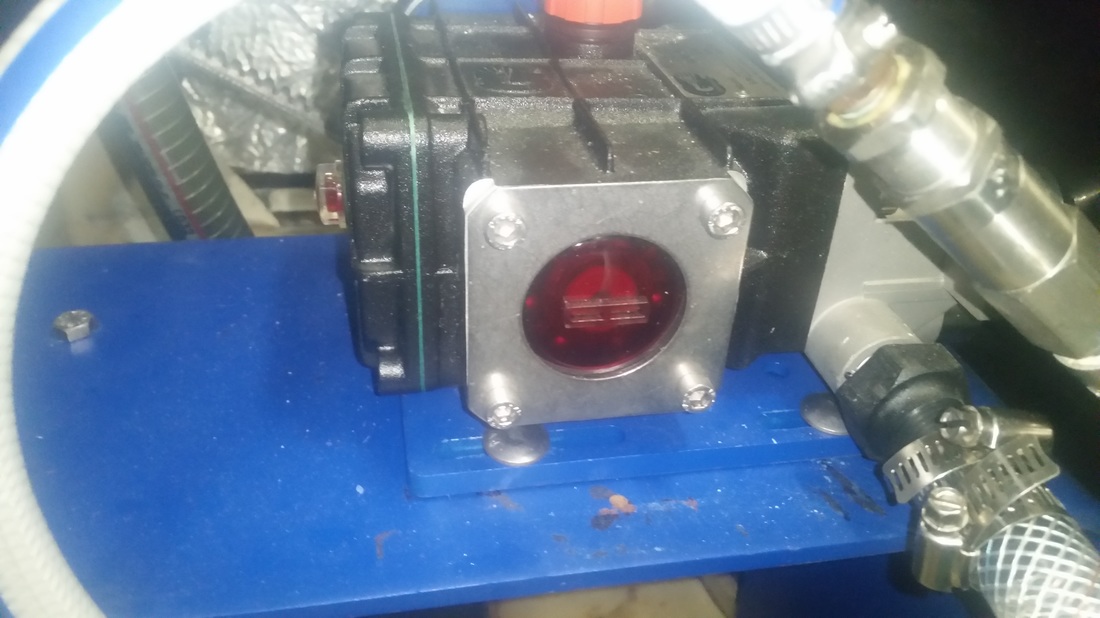

- High flow, high pressure pump

- Boost Pump

- Pre filtration

- Flush System

- Pressure Relief Valve to protect the system

- Carbon Fibre /2000 psi – Membrane Pressure Vessel

- High pressure hose with chafe resistant sheathing

- Pickling solution

- Extra 5 micron seawater filter

- Complete Installation/Instruction Manual

Optional:

- Additional Membranes 160 and 240 litre per hour production rates

- High Output Membranes 115 litres per hour

- Automatic Flush System - flush for 2 minutes every 7 days

- Extra 20 micron pre filter

- Sliding Base Plate - for horizontal belt tensioning

- Pivot Bracket - for vertical belt tensioning

All Open Ocean water makers have manual flush systems as standard. However, an automatic flush system is available as an option.

Units are modular in design allowing you to utilize unused areas. Increase your fresh water production from 80 ltrs per hour to 240 ltrs per hour by simply adding extra membranes.

Open Ocean is of the belief that water makers are no longer a luxury item, but an essential piece of equipment to provide superior quality water for all of your requirements.

Components included:

- Control Panel

- High flow, high pressure pump

- Boost Pump

- Pre filtration

- Flush System

- Pressure Relief Valve to protect the system

- Carbon Fibre /2000 psi – Membrane Pressure Vessel

- High pressure hose with chafe resistant sheathing

- Pickling solution

- Extra 5 micron seawater filter

- Complete Installation/Instruction Manual

Optional:

- Additional Membranes 160 and 240 litre per hour production rates

- High Output Membranes 115 litres per hour

- Automatic Flush System - flush for 2 minutes every 7 days

- Extra 20 micron pre filter

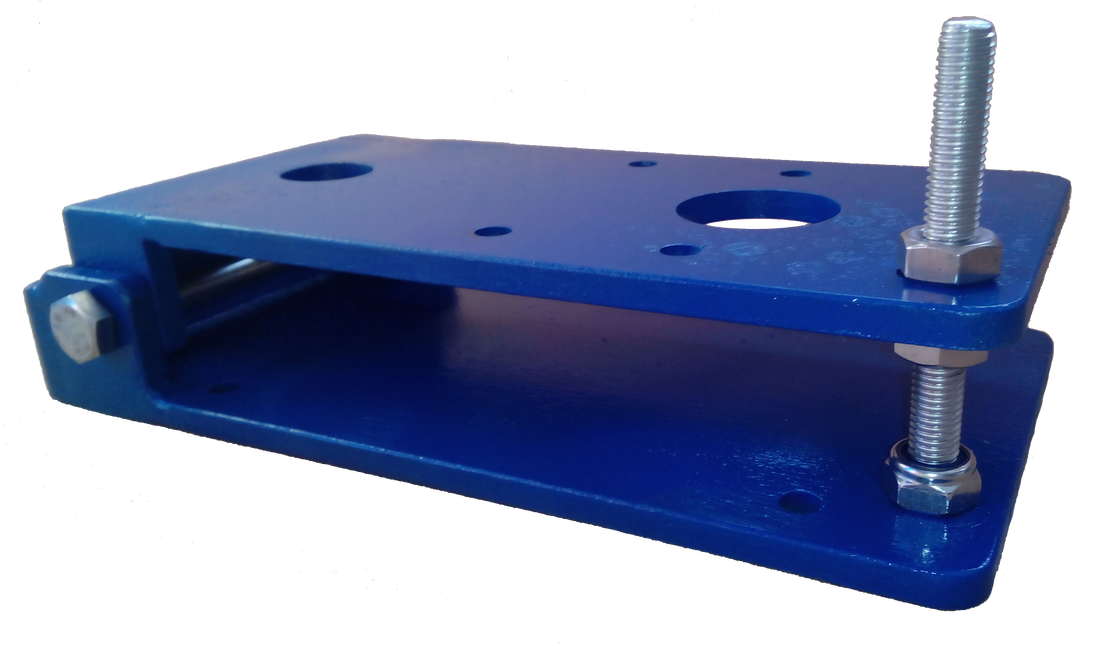

- Sliding Base Plate - for horizontal belt tensioning

- Pivot Bracket - for vertical belt tensioning

Data Sheets

| quencher_engine_drive_system.pdf | |

| File Size: | 533 kb |

| File Type: | |

Your browser does not support viewing this document. Click here to download the document.

| engine_drive_-_facts_and_figures.pdf | |

| File Size: | 296 kb |

| File Type: | |

Engine Drive Options

|

Engine Drive Sliding Base Plate

The challenge with installing an engine drive system is mounting the high pressure pump as a power take-off on the engine or generator. Every boat engine will have its own possibilities for mounting a power take-off. Our sliding base plate may help your high pressure pump installation become a little bit easier. CNC cut from 8mm aluminium, mild steel, or stainless steel, our base plate offers 50mm of sliding belt adjustment. Perfect for horizontal belt tensioning. |

| ||||||

Installation Photos

|

|

|